Choosing the Right Fastener for Chain Link Fencing

Chain Link Fencing

Fasteners play a critical role in maintaining the structural integrity and stability of the fencing, directly impacting its ability to withstand environmental pressures, such as wind, rain, and mechanical stress. Using the wrong type of fastener can lead to many problems, from premature rusting and weakening of the fence structure to complete failures.

Selecting Fastener Type

Several fastener types are particularly ideal for chain link fencing applications: hog rings, c-rings, and easy twist ties/barb edges.

Let’s outline the differences between these two.

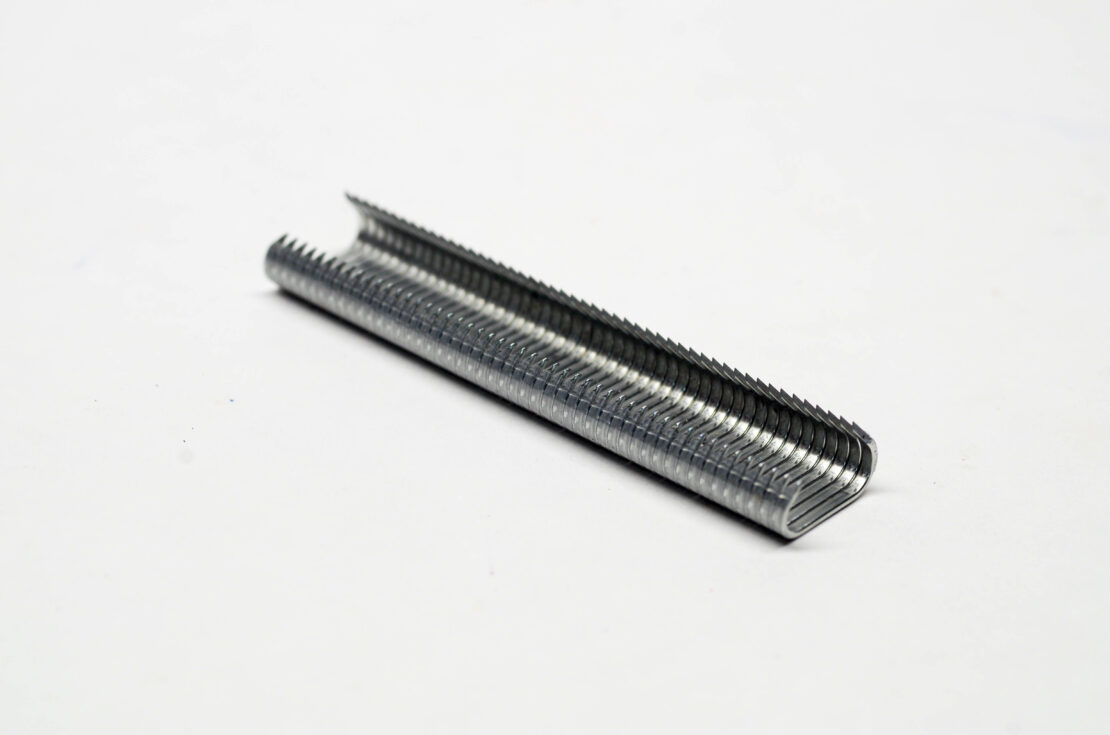

Hog Rings

Hog rings are particularly suited for securing fencing fabric to line wires, ensuring the mesh remains tight and evenly distributed. These fasteners are primarily U-shaped and made from heavy-duty metal, which is bent into a circular form to clasp the fencing tightly against itself or to the supporting framework.

When to Select Hog Rings

- You need a quick and easy installation.

- You need a permanent solution (hog rings are difficult to remove or adjust after they’ve been installed).

When Not to Use Hog Rings

- You need a temporary solution.

- You don’t have the right tools or aren’t willing to purchase specialty tools—if they aren’t installed correctly, the pressure exerted by the hog rings can damage the wire of the chain link.

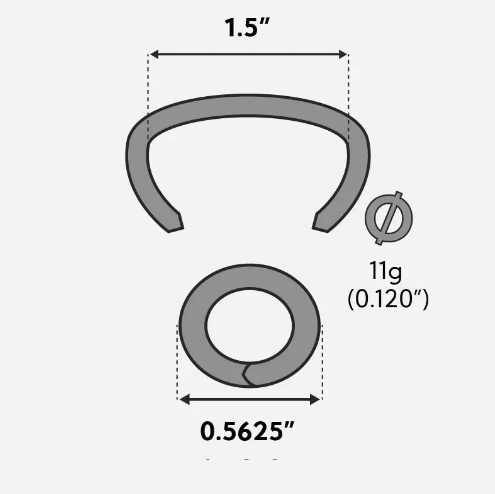

C-Rings

While C-rings are technically a type of hog rings, they offer a design variation that is particularly beneficial for certain chain link fencing applications. Like their U-shaped counterparts, C-rings are made from strong, durable metals but are shaped more like a C, allowing for a slightly wider opening before clamping.

When to Select C-Rings

- You are working with thicker materials or double layers of wire.

- You need a permanent solution.

When Not to Use C-Rings

- You don’t have a C-ring gun or aren’t willing to purchase one, which increases the risk of over-closure.

- You need a temporary solution.

Easy Twist Ties/Barb Edges

Easy twist ties, also known as barb edges, typically come as pre-cut lengths of wire with sharp points or barbs at the ends that penetrate and grip the fencing material.

When to Select Easy Twist Ties

- You need a non-permanent solution (barb edges can be easily adjusted after installation).

- You’re looking for a more affordable option.

- You need something that doesn’t require tools.

When Not to Use Easy Twist Ties

- Your fencing is in a high-security area (easy twist ties don’t provide as much tension as hog rings or c-rings).

Material

Material composition is another critical factor to consider as it influences the fastener’s durability, environmental suitability, and corrosion resistance.

Stainless steel, galvanized steel, and aluminum are the three most popular material choices for fasteners.

Stainless Steel

Stainless steel is highly durable and strong, making it ideal for applications requiring longevity and resistance to physical stresses. It also performs well in many environments, particularly in coastal areas where salt air is prevalent or in regions with high humidity. It offers the best corrosion resistance due to its chromium content, which forms a passive layer of chromium oxide on the surface.

Galvanized Steel

Galvanized steel is treated with a protective zinc coating, which improves its strength and makes it a solid choice for heavy-duty applications. This material is particularly suited for areas that do not experience extreme moisture or chemical exposure that could wear away the zinc coating. The same zinc coating acts as a barrier and sacrificial anode, which means it will corrode in place of the steel, significantly increasing the material’s lifespan against rust.

Aluminum

While not as strong as stainless steel, aluminum is sufficiently durable for most residential and some lighter commercial fencing needs. It’s lightweight and does not rust, making it suitable for environments with significant rain or moisture. It naturally generates a protective oxide coating that shields it from further decay, though it is generally less robust than stainless steel.

General Tips on Choosing a Material

- Stainless steel is generally the best all-around choice for high durability and corrosion resistance, making it a safe bet for most applications.

- Aluminum is suitable for less demanding or temporary installations.

- Galvanized steel is cost-effective and provides moderate corrosion resistance, although it shouldn’t be used in extremely wet or chemical environments, as it will wear faster.

Point Type

You’ll also need to choose between blunt and sharp points. Each point type has distinct characteristics suited for different needs and situations.

Blunt

Blunt points have rounded or flat ends, making them less likely to pierce or tear the material they secure. They are ideal when safety is a concern, such as in public or residential areas, and are commonly used in securing privacy slats or vinyl coatings where the integrity of the material needs to be maintained.

Sharp

Sharp points, as the name suggests, have a pointed end that can easily pierce through materials, which makes installation quicker. Their penetrating capability is particularly useful in thick or layered materials where secure attachment is essential. This point type is often favored in more industrial or security-focused applications where the fastener needs to anchor firmly into tough materials.

General Selection Tips

- Sharp points are better in high-security areas or where strong wind resistance is needed.

- Blunt points are preferable for delicate materials that might tear or puncture, while sharp points are better for tougher, denser materials.

- Sharp points are better in large-scale or time-sensitive projects, as they are easier to install.

Size

Lastly, you need to consider the size of your fastener. Fasteners are generally available in 1/4, 1/2, 3/4, and one-inch sizes, although some can be even bigger.

When choosing a size, evaluate the thickness of the chain link fabric. Thicker wires and more robust frameworks require larger fasteners. Measure the diameter of the wire and the width of the links to guide your selection. Also, consider load requirements. For areas subject to high winds or mechanical stress, larger fasteners can provide the additional strength needed to prevent the fence from coming loose.

Smaller sizes may be needed, especially in residential areas, to reduce aesthetic impact. However, your primary concerns should be material compatibility and load, as the entire purpose of a fence is to provide security.

Buy Fasteners for Your Project Today

Buy high-quality chain link fasteners from King Steel Fasteners. We offer aluminum, stainless steel, and galvanized steel hog rings, C-rings, and easy twist ties in various sizes. Visit our website to browse our complete inventory. Please contact us today if you need help selecting the right fastener.

Disclaimer:

King Steel Fastener’s website is not yet updated with our easy twist tie options—please reach out to us today if you’re interested in purchasing easy twist ties and one of our product specialists will contact you shortly.